Making Concrete Smooth and Shiny

Making Concrete Smooth and Shiny

If you're looking for the perfect finish, you should take the following specific steps.

Step 1: Level The Concrete

Once you've laid the concrete, you must level it. Two common tools used to level freshly laid concrete are the screed board and darby. The screed may be a piece of aluminum or simply a flat board that you use to draw over wet concrete. Darbys are basically enormous trowel that has an extended, narrow strip and two or more handles that cover a large space.

First, you must get your concrete level by taking your screed board and then pushing it across the concrete's surface. The screed can help to fill in any holes on the concrete's surface and will also eliminate any concrete that is not needed. After that, you can use the darby to smooth the concrete more.

It's recommended that you move your darby with an arc and make sure it's in a straight line so that you don't leave any marks on the surfaces. This should be done before the free water of the cement mix, referred to as "bleed water," rises onto the surface of the concrete.

Step 2: Waiting For The Water To Bleed Off

It is now time to allow the water to build up on top of the surface of the concrete before moving on to the next stage of smoothing the concrete. The bleed water will disappear by itself; however, the amount of time will depend on the properties of the concrete and the conditions in the environment.

It's crucial to wait for the water that dries from the bleed to completely evaporate; else, you're at risk of causing problems such as scaling, dusting and delamination in future.

Step 3: Float The Concrete

Floating concrete is an important step in achieving smooth surfaces. Using a screed and darby will give you a level surface. Floating can help to smoothen any imperfections, as well as compact the concrete and make it ready for further final steps. Concrete can be floated using your hands or use the aid of a machine.

If you are floating concrete with your hands using hand floats, you can choose to use smaller hand floats or larger floats. While a primary hand float made of magnesium will work well for smaller surfaces, it is possible to consider using the bull float on larger surfaces to make sure that the aggregates are able to settle.

A bull float comes with a handle with a long length that allows you to pull or push it across the concrete. A bull float is typically 10 inches wide and can be up to 10 feet in length.

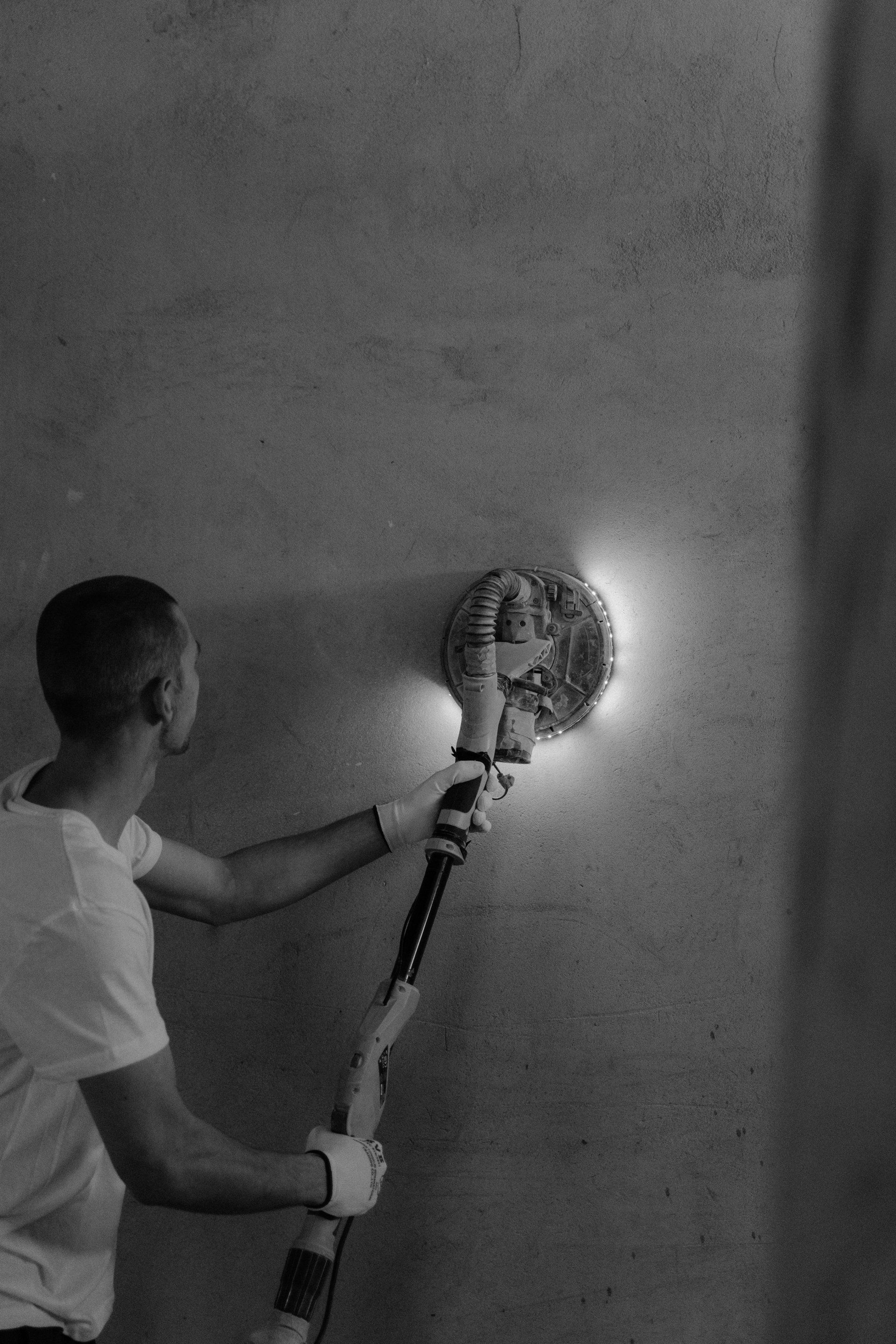

The method of mechanical floating is getting more and more popular, but the concrete needs to be a bit more firm before you try the process. The machines are large, flat floats that are made from metal, which smoothens the concrete and leaves very thin circular markings.

To make sure that your concrete has enough moisture to support the machine's weight, you can apply pressure to the concrete with your shoes. If the impression is less than 3mm, it is safe to allow the machine to flotation.

Step 4: Trowel The Concrete

Troweling is essential in indoor concrete. In this instance, you're using a floating trowel or trowel for flooring. The way to achieve the smoothest finish is by troweling with consecutive sweeps using trowels made of steel and increasing your pressure while you move along.

Make sure to not turn the trowel in the direction you go, as you'll end up creating a "chatter" texture, which isn't an even surface. Don't forget to add water to the concrete before making it.

Step 5: Allow The Concrete To Cure

After you've completed the steps necessary to finish, you can now let the cement to set. When it is fully cured, only then can you proceed to polish it.